PON ENGINEERS PVT. LTD. Offers customized solutions using the most up to date technologies. With its rich experience we are very much adaptive to the customer requirements to offer the best technical solutions at the most competitive price.

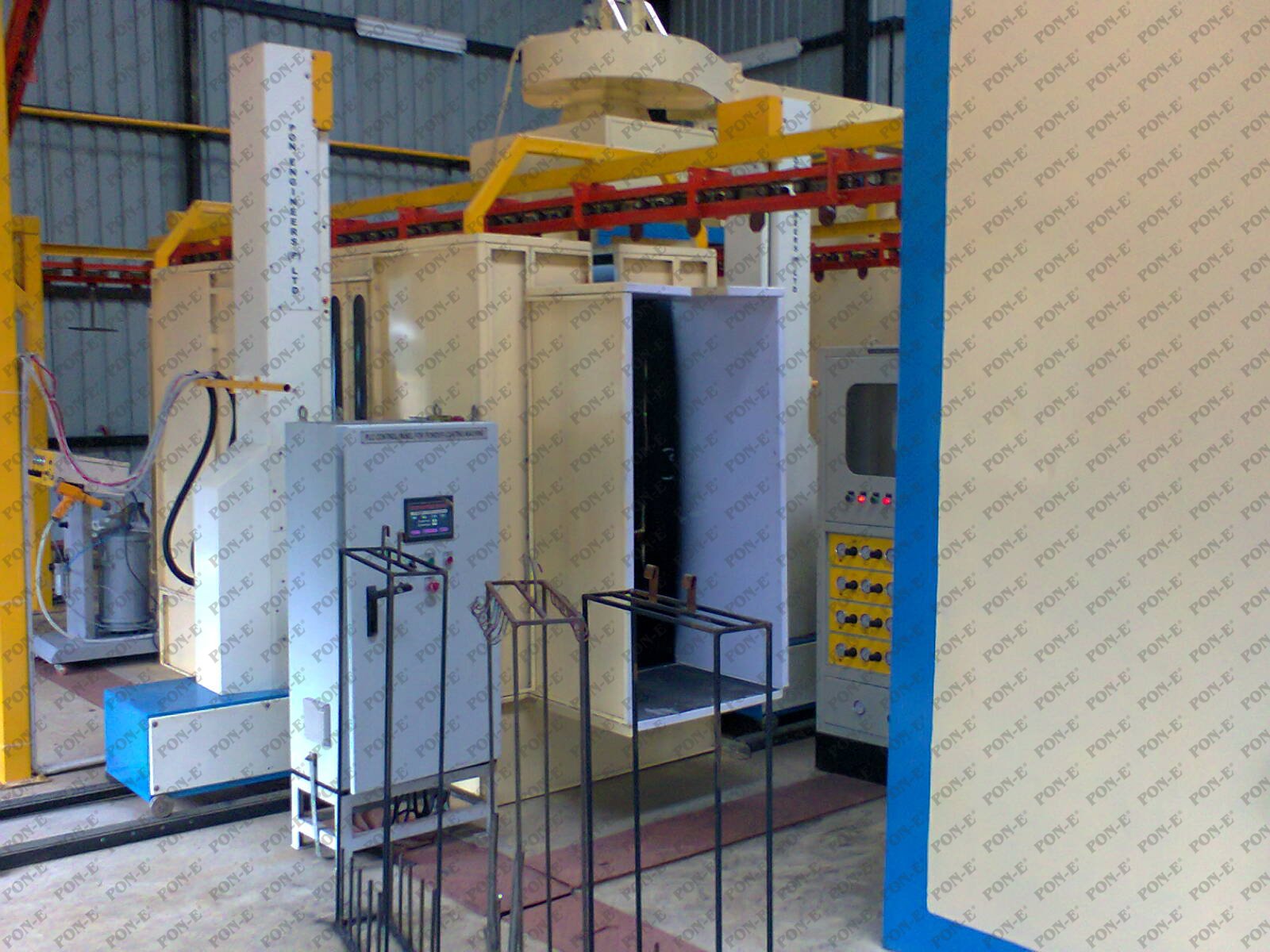

We provide Complete Solutions for Powder Coating Systems such as Manual or Automatic Powder Coating Plants. We are manufacturing wide range of products like Reciprocators (Single or Double axis version), Automatic Feeding and Sieving Machines, Powder Coating Guns, Powder Curing Ovens, High Voltage Monitors, L.P. Gas Fired Tube Heaters etc...

We have our own state-of-the-art manufacturing facilities in our factory located in Chennai, Tamilnadu.

Pon Engineers Pvt Ltd offers Electro Coating Technology which is continuously relied upon to meet the challenges of today’s competitive surface finishing market. Electro coating offers significant advantages over other finishes.

The ability to coat complex surface evenly allowing end users to maximize performance and minimize cost.

Closed loop rinsing allows transfer efficiency in excess at 95%, with dramatically reduced waste water streams.

Electro coating technology used worldwide to achieve high quality low cost finishes, at a level of efficiency and environmental compliance no other finishing method approaches.

It is an immersion coating process used to apply a thin controlled coating on metal parts. The coating material is a water based solution that is applied by dipping the parts into a paint filled tank and applying electrical current to create a flow from a set of electrodes to the part. The flow of current creates opposite polarity between the working electrode, the part and causes the paint solids in the bath to deposit on the surface parts.

Electro coat systems are highly automated and provide exceptional correction protection with modest environmental emissions like other surface coating process.

Powder Coating is a method of applying a protective or decorative finish onto a manufactured product. Powder coating materials are finely ground particles of pigments resins, binders, fillers and hardens.

Powder coatings that are applied for decorative purposes use electrostatic spray application equipment. Spray application uses a delivery system to bring powder to spray gun and a charging system to impart electrostatic charges, in most current corona charging systems for electrostatic application. As the powder passes through the electrostatic field, it picks up a charge and is attracted to a ground substrate. The electrostatic spray application system required a pre treatment method to prepare the part surface for coating, an application system to apply the powder, a booth with recovery system to contain the process and a curing oven to cross link the material and conveyor.

Pon Engineers Pvt Ltd offers Conveyorised Powder Coating Systems are designed for higher volume operations. Belt conveyor, Chain-on-edge conveyor and overhead conveyor are used in powder coating systems.

The most common type of conveyor for powder coating is the continuous speed, overhead system. These systems use a conveyor drive to power the product through the system with a fixed or adjustable line speed. Proper design and construction are the first steps towards a successful and profitable powder coating system. Each powder coating system is unique in both design and application based on the specification the user provides to the powder equipment.

Supplier determine the parameters of the system design. Information should always include All part dimensions, Line speed, Film builds requirement, Type of hooks, Conveyor height, dimensions of space provided for system installation. Production schedule based on batch sizes and number of colors involved and projected production requirement for the future. This enables the equipment supplier to design a system to exact specification for many years of utilization.

FAST Heat up and EXCELLENT Temperature UNIFORMITY

PON ENGINEERS Ageing ovens are designed to deliver rapid, complete ageing of every profile in every batch—translating into maximum profile quality. Our ageing ovens feature high-volume air systems that bring loads to temperature quickly. The heating process also occurs with exceptional uniformity throughout the load.

Aluminium Aging is a relatively low temperature operation. The parts are heated using re-circulated air and then held at temperature convection is especially effective in aluminium processing because of the very high thermal conductivity. Aluminium will accept heat virtually as fast as it can be delivered via will be optimized. This reduced the oven cycle time.

Power coating on metal surface( Aluminum, Stainless steel, etc.) as a base color. Secondly, to put power coated metal into film with sealed sides. Thirdly, into vacuum system. Vac-pumping twice and hold on for 3-5 minute, and then, to pull out metal material.

Through vacuum system, the pattern of heat transfer film, including wood grain, marble, and other etc., will be transferred on the surface of metal (Aluminum profile). The whole metal materials show high grade decorative effect.

FEATURE

Good wood feel and nature look. Environmental protection, no dust, no paint, no drugs or paint and volatile chemical composition, Waterproof, resistant to moisture, wear, corrosion resistance, Simple to use neat, efficient.

USED RANGE

Aluminum decorative plate, Aluminum wall panel, Aluminum cabinets, metal profiles, metal panels, metal curtain wall panels

Power coating on metal surface( Aluminum, Stainless steel, etc.) as a base color. Secondly, to put power coated metal into film with sealed sides. Thirdly, into vacuum system. Vac-pumping twice and hold on for 3-5 minute, and then, to pull out metal material.

Through vacuum system, the pattern of heat transfer film, including wood grain, marble, and other etc., will be transferred on the surface of metal (Aluminum profile). The whole metal materials show high grade decorative effect.

Liquid industrial coatings are often applied on automated paint line. The three major components of a paint line are pre treatment, application and cure. The exact nature of a particular paint line and the specific equipment used is determined by the job to be done. It can range from a simple spray booth with a batch oven for cure to a fully automated system that allows continuous pre treatment, application and curing.

The actual layout and specific equipment vary widely but all paint lines have the same general stages: loading area, pretreatment or cleaning stage, curing stage and unloading area.

The loading and unloading stages are where parts are put on and taken off the paint line. The pretreatment stage is where the parts are prepared for the coating application stage.

Cleaning can be done mechanically such as blasting or chemically by solvent washing, solvent wiping or dipping, after cleaning the parts are dried by heat or forced air or a combination of the two so that they are ready to be painted

Paint can be applied by spray method using conventional hand held spray guns, automatic spray guns. The spray equipment can be either non-electrostatic or electrostatic.

The curing stage is where the paint film is formed paints can be cured by air drying or heating oven for heating are conventional gas fired, electric and infrared etc.

PON-E curing oven are known to be best, unique and convenient design technical supremacy, structural integrity and high tech specification. Our curing ovens are considered best for preheating, curing, drying parts and components. Maximum working temperature up to 300˚C and forced air circulation. The oven achieves perfect temperature uniformity. They can be used for various applications, powder curing, paint drying, rubber curing etc.

Infrared curing systems offer many advantages over traditional heat source. The intense energy generated by the infrared source cures the thin layer of powder coating very quickly without heating products. This result is significant, energy cost saving, no air flows reduces powder runs and avoid contaminants reduced airing time and saving floor space. Uniformity is easily controlled by PLC with SCR.

Two dimensional parts with a uniform wall thickness, such as powder coated aluminium or steel panels are the simplest to heat using infrared radiation. Infrared system often allows the throughput of powder coating line to be increased.

Medium and long wave emitters are best because they produce some convection heat along with the infrared.

Polypropylene materials have low moisture absorption accommodates high and low extremes and has excellent thermal insulation properties. It is exceptionally stress and crack resistant, with excellent dielectric properties as well. Polypropylene is the lightest weight of any thermoplastic. It can be welded and thermo formed mechanically resistant and ideally suited to environments, most efficient and cost effective tank design for your application, they are also chemical corrosion resistance.